We have always been fascinated by the story of the sinking of the Titanic that took place in the North Atlantic Ocean in April of the year 1912. But, did we ever give a thought on how it was built? How many engines did it have and how big were they?

Here, Bill Hammack (a.k.a The Engineerguy) explains in-depth the mesmerizing engineering facts about the Titanic and its twins, the Olympic and Britannic. Lucky for him, he could come up with all these details from the journals he stumbled upon at the University of Illinois library.

The journals, which were written between 1909 and 1911, contain bedazing images of the construction of both the Titanic and its near identical twin, the Olympic. The scale of the engineering of the Olympic-class ships was indeed formidable, one would be easily held spellbound by its ravishing structured environment.

The story starts here in the Harland and Wolff shipyard, located in Belfast, Northern Ireland.

The Harland and Wolff Shipyard

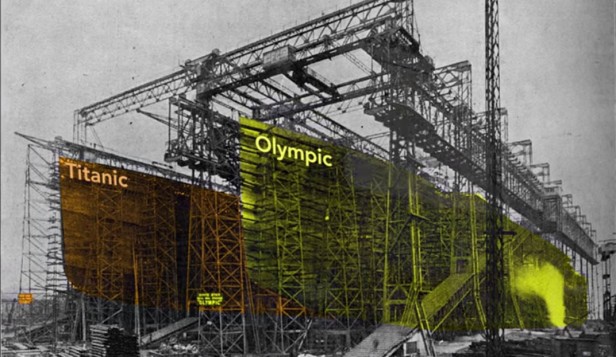

Bill Hammack explains that this large framework, known as a gantry (highlighted in orange), is where the ships were built. This gantry supports the overhead cranes and scaffolding used by workers as they construct the Olympic and the Titanic; and just beyond the stern of the gantry is the Belfast Harbor.

Workers built the Olympic on the right of the gantry and then nine months later, before the Olympic was finished, they started the Titanic on the left.

When completed, the Olympic’s stern (or rear end of the ship) would point toward the harbor. The ship’s construction starts with its keel, which is the backbone of the ship and gives the ship rigidity. If we look at keel from the land-side we see keel blocks that support it. These wooden blocks, typically pine, separate the ship from the slip – the concrete floor of the gantry. Each keel block stands about five feet high, so this creates a space under the ship for workers to construct the ship.

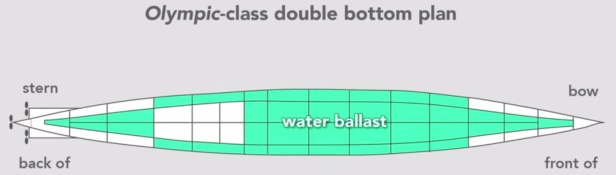

Workers built the ship outward from the keel; here they construct the Olympic’s double bottom. Here we see the framework (in pink) that separates and supports the two bottoms of the ship; the second bottom, is shown in orange.

It’s made of steel plates and is sometimes called the tank top because the double bottom contains 44 water-tight tanks. Most of the tanks carried seawater used as ballast to balance and add weight to the ship, but some carried freshwater. In total, the double bottom carried over 5000 tons of water or about 1.5 million gallons. Once they’ve finished the double bottom, workers erect the framing for the hull.

From this view we see the framing for the stern of the ship. It’s what a worker would see standing on the tank top, from the fore and looking toward the aft of the ship – that’s where the harbor is. Looking closer, we see the rib-like structure and the start of the transverse frame of the ship. Workers rivet to this frame the hull, which will form the skin. So far, this is the Olympic’s construction.

In the gantry, that ship sits in the background. In the foreground, lies the keel of its twin, the Titanic. Its construction began nine months after the Olympic. Attached to the keel, there lies the framework of the Titanic’s double bottom. Notice the large three claw like mechanism hung from cranes attached to the keel of the Titanic. These are hydraulic riveters, which workers used to install most of the three millions rivets on the Titanic.

Here we see the almost complete hulls of both the Olympic and Titanic. Work inside the Olympic progresses rapidly: the slate roof are being erected and plumbing is being fitted throughout the ship.

To prepare for the Olympic’s launch workers pain the ship a light gray so it stand out in black and white photographs, although they repainted the ship black soon after its launch so that it matched previous White Star Liners.

To ease the slide into the water, the ship was greased with 23 tons of tallow, oil and soap. And then the order to release the ship was given, the hydraulic triggers were released, and the ship slide into the harbor reaching a speed of twelve and a half knots.

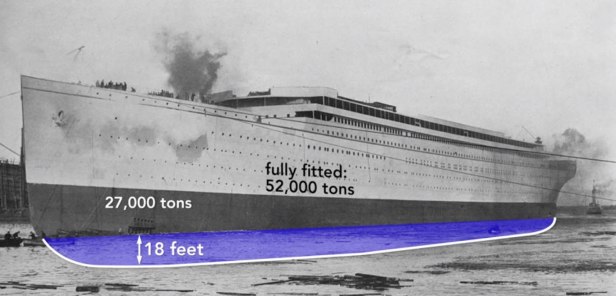

The ships are generally launched backwards, there are many reasons for this, but among them is that the stern, the rear, is wider than the bow, so it is more buoyant. In a mere 62 seconds after launch, the Olympic was afloat. The moment the ship hit the water is its official launch date, although it was mostly empty. Here it weighs only about 27000 tons and so rides high in the water. The draft – the vertical distance between the bottom of the ship and the surface of the water – is only 18 feet. After it is completely fitted it will weigh nearly twice that 52000 tons. With that additional weight, the Olympic will drop until the water reaches the border painted on the hull – a draft of about 3 feet.

The Olympic cannot move by itself and so a tugboat tows it to the fitting-out quay where gigantic crane loads the ship. The crane lifts aboard a cylindrical boiler. The final outfitting – including attaching the propellers – is done in dry dock. And then, once everything is in place, the Olympic is ready for the sea. Seven months after this launched, the Titanic was launched. The Olympic got the big press because it was first. The Titanic only becomes of more interest in retrospect.

The photograph below shows the twin, the Olympic (on the left) and Titanic (on the right). Although built side-by-side this was the last time they were photographed together.

Less than a year after the launch of these two giant ships, one suffered a collision that ripped a gaping hole in its side. That ship, was, of course, the Olympic. In September of 1911, the Olympic departed the port of Southampton, England, sailing towards the Isle of Wight. The Olympic turned into the Solent, Strait and passed a British warship, the H.M.S. Hawke. The Hawke’s commander was surprised by the Olympic’s wide turn, but he managed to take a safe position behind and to the right of the Olympic. The Hawke then increased its speed to pass the Olympic, but the Olympic’s wave sucked the Hawke inward rapidly; the Hawke tore a large hole in the Olympic. And below its waterline, the damage was even greater. The bow of the Hawke was completely smashed in. The Olympic limped back to Southampton where the holes were temporarily patched with wood, before returning to its home dock in Belfast for repairs. The Olympic’s sibling, the Britannic also suffered a traumatic blow that cause it to tragically sink.

The Britannic was the same size and very similar to the Olympic and Titanic. Although intended to be a passenger liner, the ship was draft into military service in World War I as a hospital ship. While in the Mediterranean it hit a mine or was struck by a torpedo and sank in less than an hour. Despite these accidents, the Olympic-class ships were great feats of design and workmanship.

Just consider the propulsion system of the Titanic: the ship had two sets of reciprocating engines. These engines were fueled by coal, which was stored along the bottom of the ship. Exhaust gasses from the boiler discharged through these smokes stacks, which are frequently called funnels. Now they don’t look like funnels until you look at them the right way, they are upside down funnels. This cross-section of the Olympic shows the boilers sitting atop the double bottom. Exhaust from the boilers is funneled up and out of the ship.

It is well known that the aft-most funnel on these ships is a dummy – it was built primarily for aesthetic reasons – although it did not service the boilers, it was used as a ventilation and extraction shaft for the engine and turbine rooms.

The Titanic needed 4000 tons of coal for a Trans-Atlantic trip, which took 24 hours to shovel into the bunkers. Here, in this photo of the S.S. Minnehaha, coal is being loaded into coal ports on the side of the hull. Loading coal into the Titanic worked much the same way.

This loading left streaks of coal dust on the hull and so nearly all ocean liners at the time were painted black to help hide these traces of coal. After the advent of oil fueled ships, lighter colors became more popular.

As the Titanic crossed SS France, the Atlantic, 650 tons of coal per day was shoveled into cylindrical boilers, where it was burned to produce steam. These boilers were nearly sixteen feet in diameter; this was burned to produce steam. The boilers were nearly sixteen feet in diameter.

The steam was piped to the reciprocating engines. The engines when viewed from the front of the ship, look like this.

The orange is the piston rod and inside the cylindrical casing is the piston. Excess steam from these engines was used to drive a turbine engine. This shows the turbine under construction and without its outer casing. The turbine is made of hundreds of individual blades.

A shaft transfers power from the engines to the propellers. The ones on the left and the right were powered by the reciprocating engines and each propeller weighed 38 tons. While the central propeller was powered by the turbine engine.

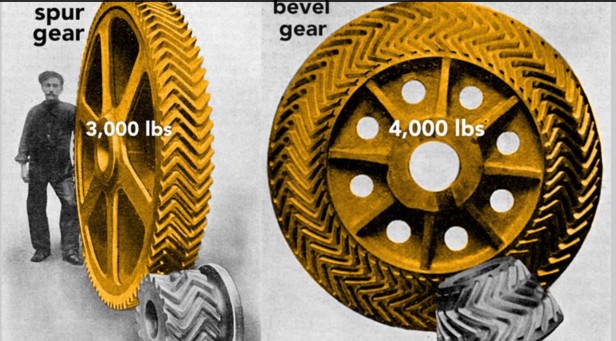

It was cast as a single piece of manganese-bronze and weighed 22 tons. The outer propellers were used for tight navigation of harbors, while the central propeller was only used in open seas. Also unlike the others, the central propeller could not be driven in reverse, only forward. Even with this powerful propulsion system, the Olympic class ships were not the fastest at the time, which was intentional. The White Star Line decided that their ships should focus on comfort and luxury over speed. It is clear that the lavishly decorated rooms on the Olympic and Titanic certainly made the passage more enjoyable, but there were some hidden design choices that made these ships the pinnacle of comfort for all classes of service. The ships were steered using these helical gears. Each ship had two sets of both the spur gears and the beveled gears. These massive gears are nearly six feet across, made of solid steel and each weight thousands of pounds.

This pattern allowed a tight engagement of the teeth and resulted in reduced vibration transmitted to the rest of the ship. Altogether, the gearing on the Titanic weighed about seven and a half tons.

This very large structural piece is call the boss arms, these arms held the shafts of the outer propellers in place, and because of their size and strength, they reinforce the hull, which reduces panting.

Panting occurs when variations in water pressure flex the hull inward and outward. Less flexing results in less vibrations felt by the passengers. These boss arms, also called shaft brackets were fitted 20 feet apart at the very aft of the ship.

While the Titanic and Britannic both had tragically short careers, the Olympic triumphed as it made 500 Trans-Atlantic journeys, carrying over 400000 passenger and sailing one and a half millions miles in its lifetime. It even spent four years as a U.S. – Canadian troop transport during the World War I. Earning the nickname “Old Reliable”. After twenty-four years of service, the ship was decommissioned and scrapped for parts. The Olympic-class ships were absolute marvels of engineering.

“I hope it’s for their revolutionary engineering, rather than their failures that the ships are remembered,” says Bill Hammack. [The Engineerguy on YouTube]

Love the photos. .

LikeLike

We went to southern ireland and drove a long long way down a road looking for Cobh almost as far as you can go and a little bit further which was the last port of call for the Titanic and couldnt help thinking about the hope of the people boarding that ship – There is a very big almost cathedral there, where you wouldnt even expect a small church and the railway line which took people to their point of departure to a new world.

LikeLike

Hi Sparkonit,

Great article, I appreciate this different perspective on these sibling ships! Also, thanks for liking my post!

LikeLike

You’re welcome and thanks for the comment, too! 🙂

LikeLike

Also awesome

LikeLike

Thank you! 🙂

LikeLike

Great Piece.

LikeLike

Thanks, pal! 🙂

LikeLike

awesome!

LikeLike

Thank you so much! Please keep visiting! 🙂

LikeLike

Titanic geeks say hurrah

LikeLike

Exactly! 😀

LikeLike

Advanced tech effort for its day.

LikeLike

Agree.

LikeLike

Fascinating 🙂

LikeLike

Thanks for the visit! 🙂

LikeLike

ciao! brilliant.

thebestdressup

LikeLike

Thanks! 🙂

LikeLike

Fascinating, thanks!

LikeLike

You’re welcome and thanks to you for the visit! 🙂

LikeLike

That was really well presented, and educationally fun.

LikeLike

Thanks to Bill Hammack! 🙂

LikeLike

Wonderful information and facts, well done.

LikeLike

Thank you! 🙂

LikeLike

Great article!

LikeLike

Thanks for reading! 🙂

LikeLike

I love this article…. brilliant!

LikeLike

Thank you, Sir! 🙂

LikeLike